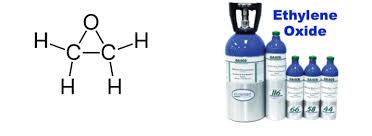

ETHYLENE OXIDE:

Ethylene oxide (EO) is a highly reactive, flammable, and colorless gas at room temperature with a faintly sweet odor. Its chemical formula is C₂H₄O. Ethylene oxide is a key industrial chemical used mainly as an intermediate in the production of ethylene glycol, which is utilized in antifreeze, polyester fibers, and plastics. Additionally, it serves as a sterilizing agent for medical equipment and supplies due to its ability to destroy bacteria, viruses, and fungi.

Despite its usefulness, ethylene oxide is highly toxic and poses significant health risks. It is classified as a human carcinogen, and exposure can lead to various adverse health effects, including respiratory irritation, headaches, nausea, and more severe long-term conditions such as cancer. Its flammability also necessitates careful handling and storage to prevent explosive hazards.

Ethylene oxide offers several advantages, particularly in industrial and medical applications. Here are the key benefits:

- Effective Sterilization:

- Ethylene oxide is highly effective at sterilizing medical equipment and supplies. It can penetrate packaging and materials that other sterilization methods, like steam, cannot, ensuring thorough sterilization without damaging the items.

- Versatility:

- It is used to sterilize a wide range of materials, including plastics, electronics, and other heat-sensitive items. This versatility makes it indispensable in medical and laboratory settings.

- Industrial Importance:

- Ethylene oxide is a crucial intermediate in the production of various chemicals, most notably ethylene glycol, which is essential in the manufacture of antifreeze, polyester fibers, and resins.

- Broad Spectrum of Activity:

- Ethylene oxide is effective against a broad spectrum of microorganisms, including bacteria, viruses, fungi, and spores, making it a reliable sterilization agent.

- Non-Damaging to Sensitive Equipment:

- Unlike some sterilization methods that use heat or moisture, ethylene oxide is gentle on delicate and complex medical instruments and electronics, preserving their functionality and integrity.

- Efficient Penetration:

- Its gaseous form allows ethylene oxide to penetrate porous materials and hard-to-reach areas, ensuring comprehensive sterilization of complex and intricately designed equipment.

- Long-Term Storage:

- Items sterilized with ethylene oxide typically have a longer shelf life compared to those sterilized by other methods, as EO can maintain sterility over extended periods if properly packaged.

These advantages make ethylene oxide a valuable resource in both industrial chemical production and the medical field, despite the need for careful handling due to its toxic and flammable nature.

While ethylene oxide offers several advantages, it also comes with significant disadvantages:

- Health Risks:

- Ethylene oxide is highly toxic and classified as a human carcinogen. Exposure can lead to serious health issues, including respiratory irritation, headaches, nausea, vomiting, and long-term effects such as an increased risk of cancer (particularly leukemia and lymphoma).

- Flammability and Explosiveness:

- Ethylene oxide is highly flammable and can form explosive mixtures with air. This necessitates strict safety measures during storage, handling, and transportation to prevent accidents.

- Environmental Impact:

- The release of ethylene oxide into the environment can have harmful effects on air quality and contribute to pollution. It is essential to manage emissions and ensure proper disposal to minimize environmental damage.

- Strict Regulatory Controls:

- Due to its toxicity and carcinogenic nature, the use of ethylene oxide is heavily regulated. Compliance with these regulations can be costly and require significant investment in safety equipment and procedures.

- Complex Handling Requirements:

- The handling of ethylene oxide requires specialized equipment and trained personnel to manage its toxic and flammable properties safely. This adds complexity and cost to its use in industrial and medical applications.

- Residue Concerns:

- Residual ethylene oxide on sterilized items can pose health risks. Proper aeration and handling procedures are necessary to ensure that any residual gas is eliminated before the items are used.

- Potential for Equipment Damage:

- Although ethylene oxide is generally gentle on materials, it can cause corrosion and degradation of certain materials over time if not properly controlled, potentially leading to equipment damage and increased maintenance costs.

- Public Perception and Controversy:

- The use of ethylene oxide, especially in medical sterilization, has faced public scrutiny and controversy due to its health risks and environmental impact, leading to pressure on industries to find safer alternatives.

These disadvantages highlight the need for careful and responsible use of ethylene oxide, balancing its benefits with the implementation of stringent safety and environmental measures.

Hey there You have done a fantastic job I will certainly digg it and personally recommend to my friends Im confident theyll be benefited from this site

Usually I do not read article on blogs however I would like to say that this writeup very compelled me to take a look at and do so Your writing taste has been amazed me Thanks quite nice post

I loved as much as you’ll receive carried out right here. The sketch is tasteful, your authored material stylish.